Unfortunately, tractors are potentially much more dangerous to operate than it appears at first glance. Tractor related accidents are annually the leading cause of death on farms in the United States. Not only is this a sobering statement, but it means that you need to pay extra attention to what’s required to operate a tractor safely. I’m thankful to say I’ve never rolled or tipped a tractor although I’ve been on three wheels several times in my life. I can tell you that the “pucker” effect is very real! Many of you can relate to that feeling and I hope that none of you ever experience a rollover. I’d like to make it clear that this article is not a recommendation on how to properly ballast and operate your tractor, but rather an informational piece to encourage you to take ballast weight very seriously as part of safe tractor ownership.

Ballast weight or counter weight can be accomplished by many different means and in most cases will require a combination of methods to satisfy the MINIMUM ballast weight requirement. In fact, as I researched tractor manuals for this article, I was unable to find a single machine that could meet the bare minimum listed by using only one type of ballast. However, first we should step back and get a simple understanding of ballast weight. It is defined as a material or substance positioned on a vehicle or structure to create balance and stability. In simpler terms, think of a teeter totter with a small child on one side and a large child on the other. It’s easy to see that this structure is out of balance as the tiny kid dangles his legs in the air while the big kid is planted closely to the ground. In the same manner, your loader and bucket are one side of the front axle (fulcrum or pivot) while the rest of the tractor lies on the opposite side. It’s easy to see the parallel.

However, tractor operators encounter a much more difficult and unstable environment than a stationary structure. As Newton’s First Law states, “an object in motion stays in motion.” If your structure isn’t properly balanced, then you’ll find it very difficult to operate your tractor in a safe and effective manner. Loads in your bucket will shift as you change direction, change speeds, and raise or lower the loader. Hidden ruts, holes, rocks, and stumps can create sudden changes in balance. Children, dogs, or tools might appear out of nowhere and create drastic shifts in momentum. Expecting the best, but planning for worst is a phrase that comes to mind and very fitting when operating a piece of equipment in which the consequences could be fatal. However, the cost to safely ballast your tractor could be around $1,000-$1,500 and last for the duration of your tractor ownership. Frankly, if you can afford a $20,000 tractor, then you can afford to operate it safely.

There’s many ways that you can provide ballast weight on your tractor including three point hitch attachments, wheel weights, suitcase weights, liquid ballast, ballast boxes and more. These methods will all have pros and cons including price, permanence, ease of handling, location on the machine, and so on. This list could go on forever if given the time, but we’ll narrow it down into a few categories that hit the highlights. The most expensive forms of weight will include wheel weights and suitcase weights. In fact, on a price per pound basis, these two forms of ballast weight or almost absurdly high in cost coupled with the fact that neither will meet the minimum ballast requirement on their own. Suitcase weights are possibly the easiest type of weight to handle given the most typical weights are around 42 lbs, quite manageable compared with the alternatives. With such weights, you’ll need a weight bracket in addition to the suitcase weights themselves. Know that if you choose to order anything through Heavy Hitch, you can get 5% off with discount code GWT.

Perhaps the most practical form of ballast weight is to use an attachment on the three point hitch. This would make the most sense if it were a relatively heavy attachment along the lines of a tiller, snowblower, or backhoe. Light attachments such as rear blades or box blades will help, but are a far cry from being anywhere near sufficient counter weight. Additionally, you always run the risk of damaging your attachment when using it as ballast. Whether it’s running into a hidden object or grinding it into the ground unintentionally. The benefit to using an attachment is that it then becomes a multipurpose tool acting as ballast weight when not needed and as the functional implement it was originally designed. We have a plethora of attachments that you should check out if you think this is the solution for you. Again, any 3 point attachment on it’s own does NOT meet the minimum ballast requirement.

While nothing is foolproof or a one-size-fits-all solution, I’ve found a combination that is efficient, effective, and economical. This 1-2 punch met every minimum ballast requirement found in a tractor manual that I researched. The first part is to have your tires loaded with liquid ballast. This is something some folks have done on their own, but most folks will have a local tractor dealer or tire shop handle for them. It is likely that this is the cheapest form of ballast weight available on the market today. In the south, many will use water or washer fluid, however in colder climates it’s recommended to use a solution that won’t freeze such as Rim Guard or TL90. Even liquid ballast will fall well short of the minimum ballast requirement, but the benefits of being on the tractor all the time, being an affordable solution, and freeing up the three point hitch for other counter weight attachments puts this atop all other choices for me.

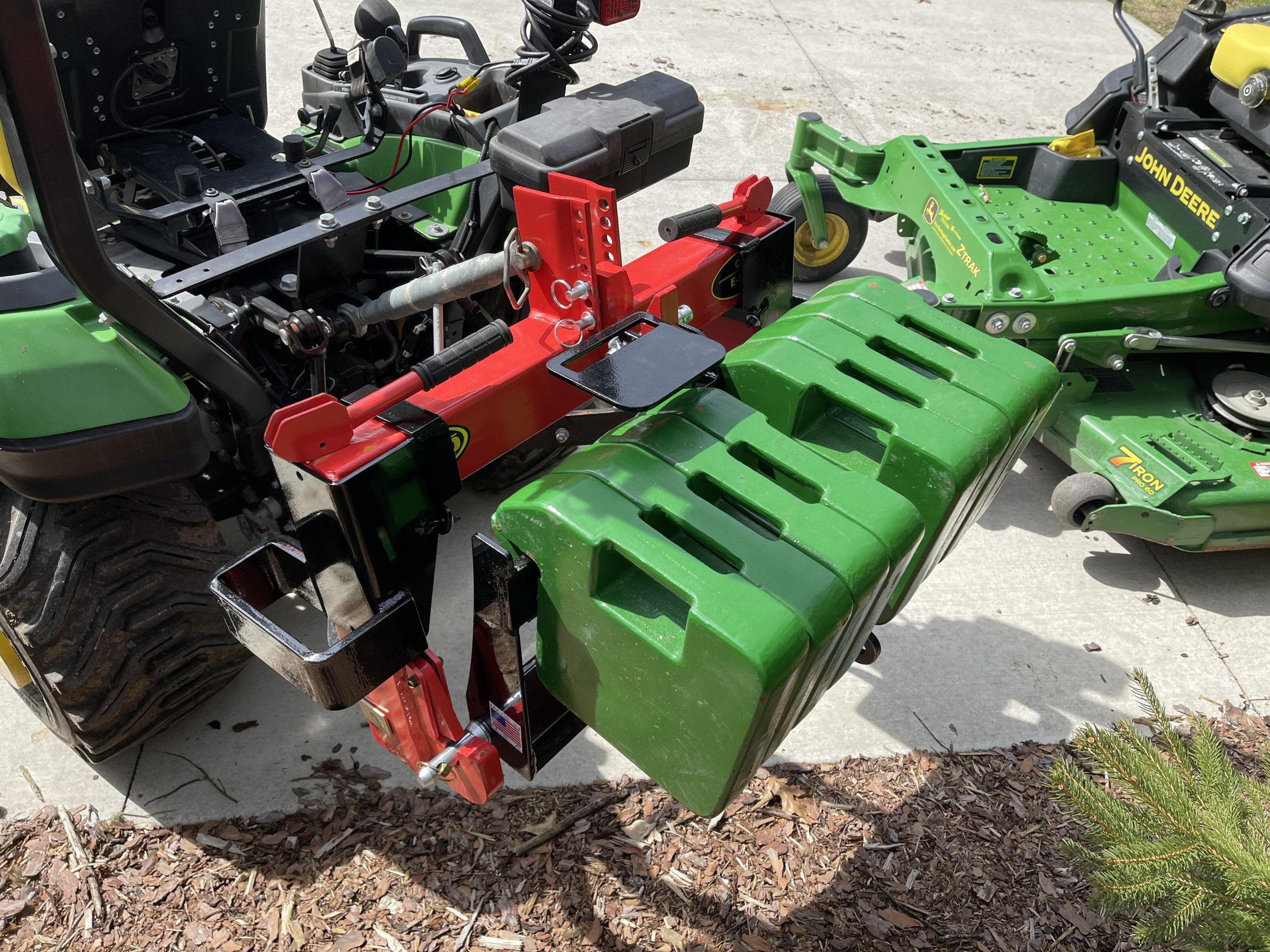

However, you still need MORE weight! This is where the combo is completed in the form of ballast weight accomplished through a ballast box. There’s many options out there for ballast boxes and I tend to lean more towards one over the rest. I’d like to qualify this statement, that I’ve done a lot of research and always look to find the best value for my customers. This means it’s at a reasonable price point, well constructed, and hopefully offers something that the competition does not. That is the case with the Ballast Box by Titan Attachments. This ballast box comes in multiple colors so you can find the right one for you as well as category 1 and category 2 ballast boxes to fit subcompact, compact, and even Ag tractors. These ballast boxes include features not found on others such as tool tubes to bring along additional tools in the field, a 2″ receiver so that you can tow another attachment behind the box, a dump door so that you can empty your ballast box when needed, and even fork slots so that you can pick it up and move it around. All of this at a very competitive price to other ballast boxes on the market plus it is also Quick Hitch compatible.

As discussed, the combination of liquid ballast weight and a 3-point ballast box (filled with material) met the minimum ballast weight requirement for every tractor manual I read while researching this subject. That does not mean it will meet your minimum ballast requirement and you should always do your own research to make that final determination. An important note to remember is that we are talking about simply doing the bare minimum and that these manuals don’t mention a maximum amount of ballast weight. So, if you aren’t at least meeting this minimal amount of counter weight, then you are potentially putting yourself into the risk or serious peril.

WATCH THE BALLAST WEIGHT VIDEO BELOW! 👨🌾🚜👩🌾

Note that there are affiliate links throughout this article. If you choose to make a purchase through some links, Good Works Tractors may receive a commission. If you choose to do so, then know that I appreciate your support! Products are hand picked as excellent values which are provided at a reasonable price, with quality construction, and desirable features.