Description

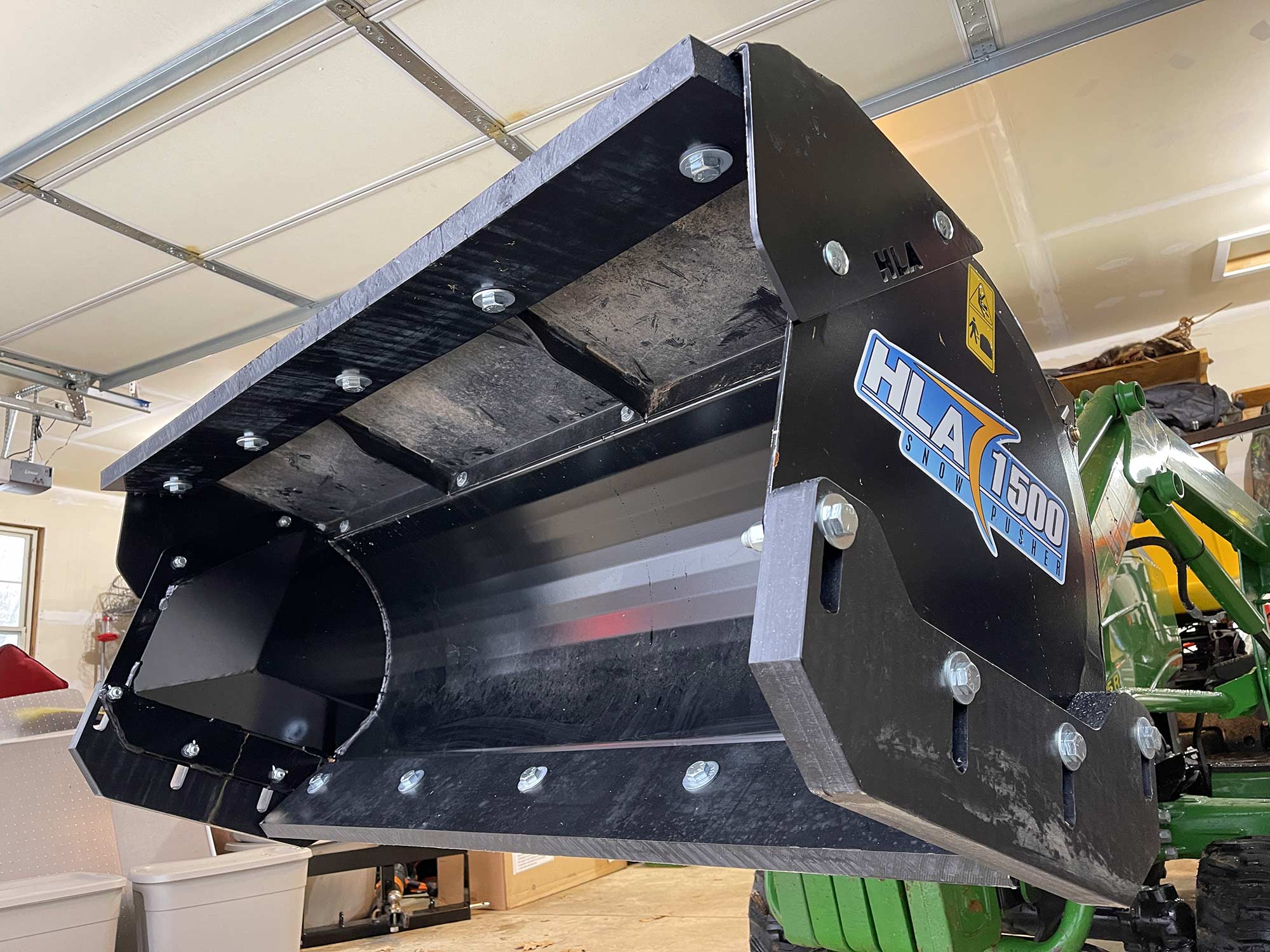

HLA SNOW PUSHER Backdrag highlights

- Totally enclosed backdrag on the 1500 and 2500 snow pusher. Not fully enclosed, but still largest-in-class on 2500 and 3500 Series.

- Reversible, replaceable, and adjustable scraping edges (steel or rubber standard, UHMW upgrade)

- Made in Canada

If you’re looking for the full Snow Pusher listing, you can find them here:

CHOOSING A CUTTING EDGE

UHMW*

Ultra High Molecular Weight Polyethylene or UHMW (sometimes called poly or plastic) is best summed up by saying “it cuts like steel, but protects like rubber.”

With great wear properties, UHMW cuts well through packed snow, is very quiet, and protective of paved/concrete surfaces. It lasts nearly as long as steel.

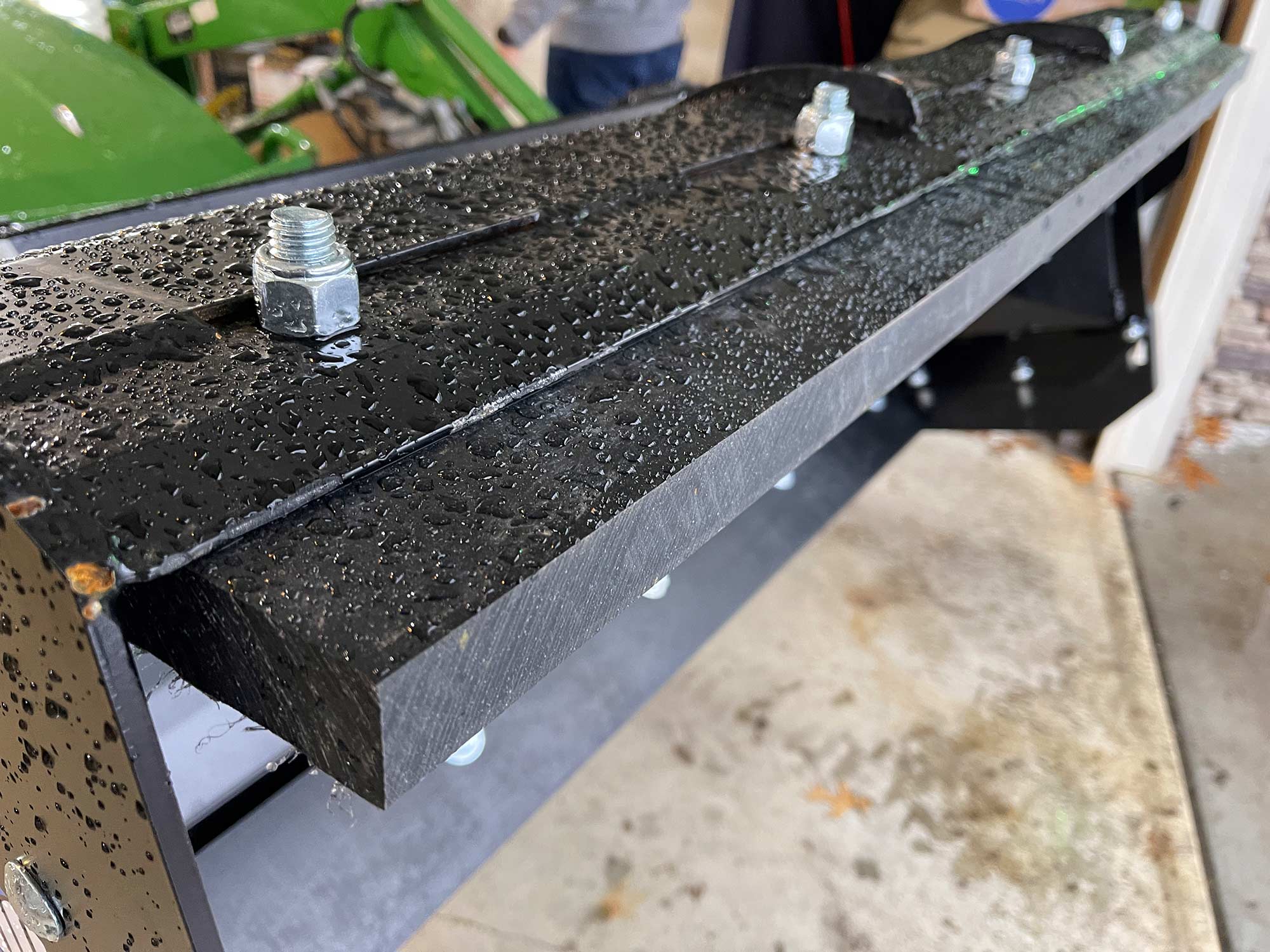

*NOTE: UHMW edges are cut to length. Hardware is included to fasten to your pusher or backdrag.

UHMW installation is easy! This material cuts similar to wood, so the same tools can be used.

Use the existing holes on the pusher components as your template. Then, drill out the piece of UHMW with a multipurpose drill bit matching the hole diameter. For backdrags and main edges, we supply bolts, washers, and lock nuts. No backer bars required.

For complete protection on pavement, asphalt, concrete or other delicate surfaces, use a combination of rubber and UHMW or all UHMW on all contact points (main edge, backdrag edge, and skid runners).

Rubber

Protective of paved/concrete surfaces, very quiet, doesn’t cut packed snow at all, shortest life span.

Steel

Wears very well, cuts packed snow very well, but is hard on paved/concrete surfaces, leaves rust stains, and is loud. Great for gravel, stone, and other unpaved surfaces.

Purchase this item and get

Purchase this item and get

Reviews

There are no reviews yet.