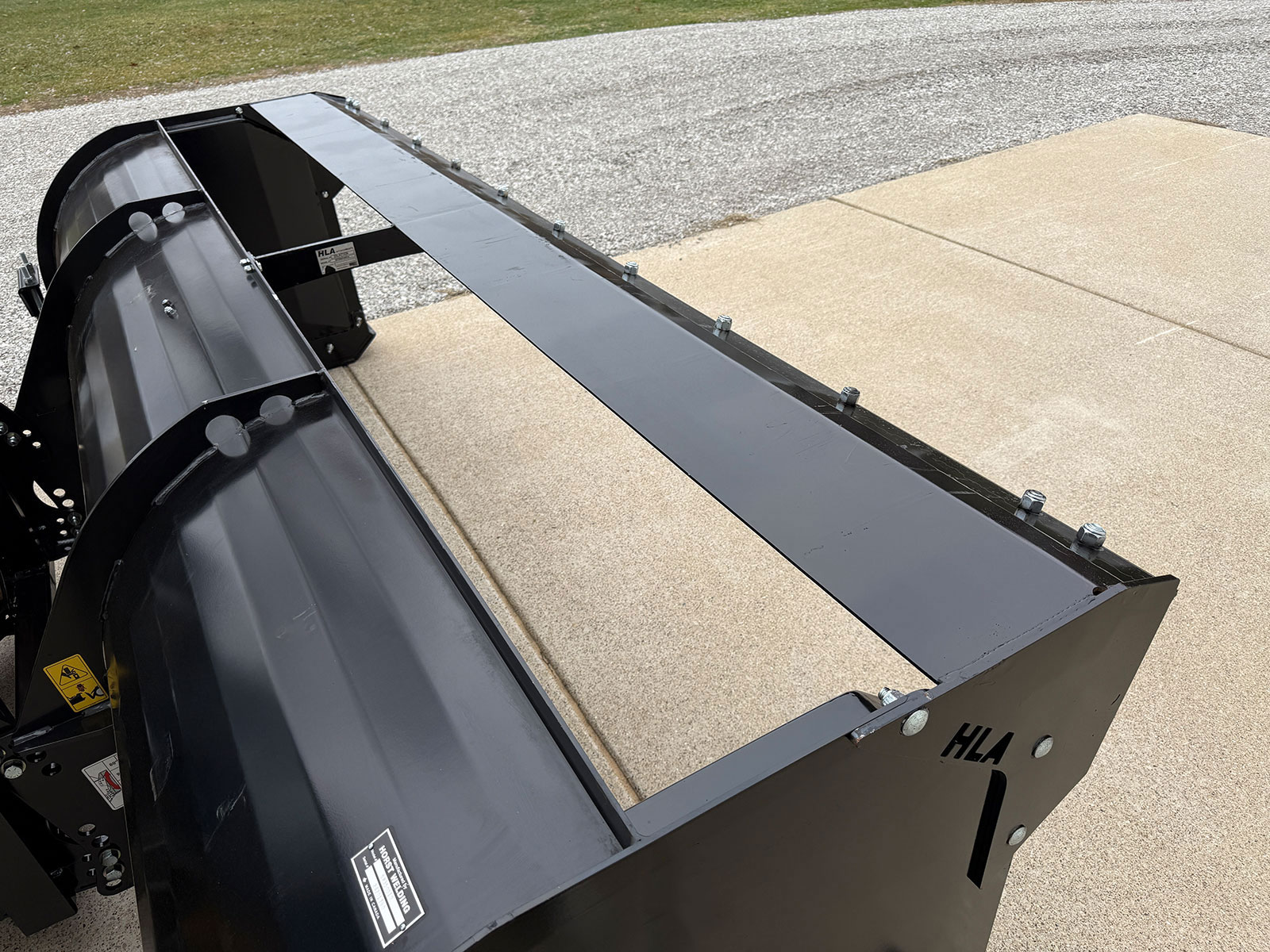

Description

Key advantages of the HLA 3400 Snow Pusher Design include:

- Radius back which releases snow instead of letting it stick

- Double-walled and tapered side panels eliminate cross braces that trap snow

- Backdrag option allows you to pull snow away from walls

- HLA’s backdrag is bigger and more rigid than any competitor’s we’ve seen

- Integrated steel edge included

- Optional replaceable steel, rubber, or UHMW edge available

- Bolt-on quick attach frame for more flexibility over time

- JDQA, SSQA, and Global

- Reversible, replaceable, and adjustable cutting edges for pusher

- Steel or rubber standard, UHMW is an optional upgrade

- Replaceable, replaceable, and adjustable skid runners

- Steel standard, UHMW optional

- Optional extra-wide steel runners for gravel surfaces

How To Decide Which Snow Pusher Works For you?

WHEN ORDERING A SNOW PUSHER, THESE ARE THE DECISIONS TO MAKE:

- Series: 1500, 1800, 2500, 3400

- Widths (in inches): 54, 60, 66, 72, 84, 96, 108, 120, 132, 144. Not all sizes available in all series

- Color: Black is stocked. For any other color color, expect a long lead time.

- Backdrag: Yes or No (we highly recommend buying this at the time of purchase, as you can remove all but the tiniest strips of snow against a building or wall with a backdrag)

- Connection Type: JDQA, SSQA in all series

- Yanmar QA only available in 1500 Series

- Global available in 2500 and 3400 Series.

- Replaceable edge for main pusher box

- Steel, rubber, or UHMW.

- UHMW is cut to length, ready for you to drill out and add your own hardware (hardware available for purchase here).

- Edge for backdrag—includes an integrated steel edge

- Optional replaceable steel, rubber, and UHMW edges

- Skid Runners

- Steel runners are included in the base price

- Optional UHMW runners available to protect your drive

- Extra Wide Steel Runners available for use on gravel surfaces, to help prevent the cutting edges from digging

- Pre-Assembly is available, so all components arrive bolted together with no assembly required by customer

- *Always adjust skid shoes for your conditions upon arrival.

*For COMPLETE protection if you are pushing snow on asphalt, concrete, or other delicate surfaces, you will want rubber or UHMW on all contact points including edges and skid runners.

Cutting Edges for Snow Attachments

UHMW

Sometimes called poly, UHMW is a plastic best summed up by saying “it cuts like steel, but protects like rubber.” Great wear properties, cuts well through packed snow, very quiet, protective of paved/concrete surfaces. Lasts nearly as long as steel.

Hardware for UHMW cutting edges available in this listing.

*NOTE: UHMW edges are cut to length, ready for you to drill out and add your own hardware.

UHMW Installation is easy! This material cuts similar to wood, so the same tools can be used. Use the existing holes on the pusher components as your template. Then, drill out with a multipurpose drill bit matching the hole diameter. For backdrags and main edges, use 1/2″ x 3″ bolts with washers and lock nuts. No backer bars required.

Rubber

Protective of paved/concrete surfaces, very quiet, doesn’t cut packed snow at all, shortest life span.

Steel

Wears very well, cuts packed snow very well, but is hard on paved/concrete surfaces, leaves rust stains, and is loud. Great for gravel, stone, and other unpaved surfaces.

| HLA Snow Pusher Specs | ||||||||

|---|---|---|---|---|---|---|---|---|

| Series | Width (in) | Pusher Weight (lb) | Frame Weight (lb) | Back Drag Weight (lb) |

Average Weight of Removable Edge (lb) |

Combined Weight (lb) |

Depth (in) | Mouldboard Height (in) |

|

1500

|

54 | 195 | 135 | 65 | 32 | 427 | 18 | 20 |

| 60 | 205 | 135 | 71 | 33 | 444 | 18 | 20 | |

| 66 | 220 | 135 | 77 | 35 | 467 | 18 | 20 | |

| 72 | 230 | 135 | 86 | 37 | 488 | 18 | 20 | |

|

1800

|

60 | 335 | 135 | 71 | 33 | 574 | 21 | 24 |

| 72 | 375 | 135 | 86 | 40 | 636 | 21 | 24 | |

| 84 | 420 | 135 | 99 | 48 | 702 | 21 | 24 | |

|

2500

|

72 | 485 | 170 | 190 | 45 | 890 | 30 | 30 |

| 84 | 515 | 170 | 215 | 48 | 948 | 30 | 30 | |

| 96 | 555 | 170 | 245 | 55 | 1025 | 30 | 30 | |

|

3400

|

84 | 865 | 170 | 255 | 55 | 1345 | 36 | 30 |

| 96 | 925 | 170 | 285 | 61 | 1441 | 36 | 30 | |

| 108 | 985 | 170 | 315 | 66 | 1536 | 36 | 30 | |

| 120 | 1045 | 170 | 345 | 70 | 1630 | 36 | 30 | |

| 144 | 1190 | 170 | 405 | 75 | 1840 | 36 | 30 | |

IF YOU WANT MORE TRACTION (AND SAFETY) READ ON…

Every tractor utilizing a front-end loader needs counterweight. How much is specified in your tractor or loader manual. But in addition to safety, counterweight will improve your traction significant, something especially critical during the snowy months of the year.

Shop our Ultimate Weight Bundle to get huge savings when you combine counterweight solutions.

Extended Warranty

Extend the standard manufacturer’s warranty coverage to the stated period shown at purchase.

Lifetime Warranty

Extend the standard manufacturer’s warranty to for the lifetime of the product.

What is covered

Your warranty covers issues stemming from the craftsmanship of the product, like broken welds, torn steel, or improper fit. Tractor attachments are generally designed to be used in harsh environments, so normal wear-and-tear is not covered (things like lost paint or chipped paint, scratches, dents, or bent teeth).

We will repair or replace, at our discretion, your attachment/product under the warranty purchased.

What isn’t covered

Any shipping necessary for repair or replacement, as well as transportation costs are not covered under the factory warranty. Lost time and down time are not covered. Replacement parts are covered, but not labor costs.

If damage occurs from improper use (a use other than what the product is marketed for), the warranty is void. Damage caused to your tractor while using an attachment will not be covered.

Your warranty is non-transferable, meaning it exists as long as you’re the owner and operator of the product.

Purchase this item and get

Purchase this item and get

Reviews

There are no reviews yet.